Carbon Molecular Sieve

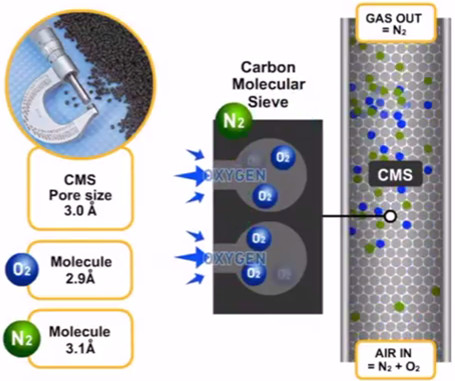

Carbon molecular sieve is a type of porous material that is composed of accumulated carbon element.The structure of its

internal micropores hava a characteristic of selective adsorption to oxygen molecules,so that it is used as adsorbent for

the separation of nitrogen and oxygen.Use arbon molecular sieve as adsorbent for nitrogen separation also is known as

psa nitrogen generation. Since it take a series of advantages,low invest,low cost,speed running and flexible adjust of

nitrogen purity.Therefore it is widely used in the fileds of coal mine,petrolium,chemicals,metal heat-treatment,

electronics production and food fresh preservation.

Carbon molecular sieve classfied in three types according to the

differences of raw materials.

1-) Carbon molecular sieve 100% made from coconut shell

2-) Carbon molecular sieve made from blending of coconut shell

and phenonic.

3-) Carbon molecular sieve 100% made from phenonic resin

Above carbon molecular sieves performance is similar,the main

difference is that carbon molecular sieve made from

coconut shell well meet the requirement of enviromental protection

in the process of nitrogen generation.

Hotek Chemical Technology Co.,Ltd. would like to guarantee all its supplied carbon molecular sieves are 100% made from

coconut shell to response for the calling of global enviromental protection.

In order to well meet its applications in various fields,Hotek produced carbon molecular sieves is divide into three

performance levels according to its nitrogen generation capability

|

+ Basic Performance CMS (Particle Diameter) 1.3~1.8mm CMS230 Ask for Technical Data

+ Medium Performance CMS (Particle Diameter) 1.3~1.8mm CMS240 Ask for Technical Data

+ Medium Performance CMS (Particle Diameter) 1.3~1.8mm CMS260 Ask for Technical Data

+ High Performance CMS (Particle Diameter) 1.0.-1.1mm CMS280 Ask for Technical Data

|

SPECIFICATION

|

Diameter

|

1.0-1.3mm

|

|

Bulk Density

|

670-690g/l

|

|

Adsorption Rate

|

2*50s

|

|

Crush Strength

|

≥100N

|

|

Type

|

Adsorbent pressure

|

Purity of Nitrogen

|

Rate of Nitrogen Prodution

|

Nitrogen Recovery Rate

N2 (%)

|

|

(Mpa)

|

N2 (%)

|

N2 (m3/h.t)

|

|

CMS-185

|

0.8

|

99.99

|

58

|

2.1

|

|

99.9

|

115

|

3.1

|

|

99.5

|

185

|

4.0

|

|

99.0

|

245

|

4.5

|

|

98.0

|

300

|

4.6

|

|

97.0

|

355

|

4.8

|

|

CMS-200

|

0.8

|

99.99

|

80

|

2.1

|

|

99.9

|

130

|

3.1

|

|

99.5

|

200

|

4.0

|

|

99

|

275

|

4.5

|

|

98

|

325

|

4.6

|

|

97

|

330

|

4.8

|

|

CMS-220

|

0.8

|

99.99

|

100

|

2.1

|

|

99.9

|

150

|

3.1

|

|

99.5

|

220

|

4.0

|

|

99

|

280

|

4.5

|

|

98

|

335

|

4.6

|

|

97

|

350

|

4.8

|

|

CMS-240

|

0.8

|

99.99

|

110

|

2.1

|

|

99.9

|

170

|

3.1

|

|

99.5

|

240

|

4.0

|

|

99

|

305

|

4.5

|

|

98

|

365

|

4.6

|

|

97

|

380

|

4.8

|

|

CMS-260

|

0.8

|

99.99

|

120

|

2.8

|

|

99.90

|

175

|

3.6

|

|

99.50

|

260

|

4.6

|

|

99.00

|

320

|

5.3

|

+ Long service life,Hotek guarantee 5~8 years service life of its carbon molecular sieve on the basis of proper operation.

+ Enviromental protection,Hotek carbon molecular sieve meet the requiement of enviroment protection since its carbon

molecular sieve is 100% made from coconut shell.

+ Regular size,Hotek carbon molecular sieve particle diameter tolerance could controlled within + 0.02mm.

+ Consistent performance,Hotek carbon molecular sieve of each batches keep condistent performance.

+ Less ash content, Huatai carbon molecular sieve with low ash containment is good for the maintenance of nitrogen

generator as well as the prodcution enviromental protection.